The Skilled Labor Shortage: A Key Challenge in Construction

The construction industry faces a historic challenge: a national shortage of skilled labor. This shortage increases costs, delays timelines, and limits the ability to scale projects. TMBR’s solutions address this head-on by:

Simplifying Assembly: Prefabricated components and clear instructions reduce the need for highly specialized labor on-site.

Reducing Labor Demands: By optimizing workflows through digital tools, TMBR minimizes time spent on manual tasks.

Enabling Faster Timelines: Streamlined processes ensure that projects are completed efficiently without sacrificing quality or scalability.

For more on how TMBR addresses workforce challenges, see Solving Labor Shortages: Modular Construction at Scale with TMBR.

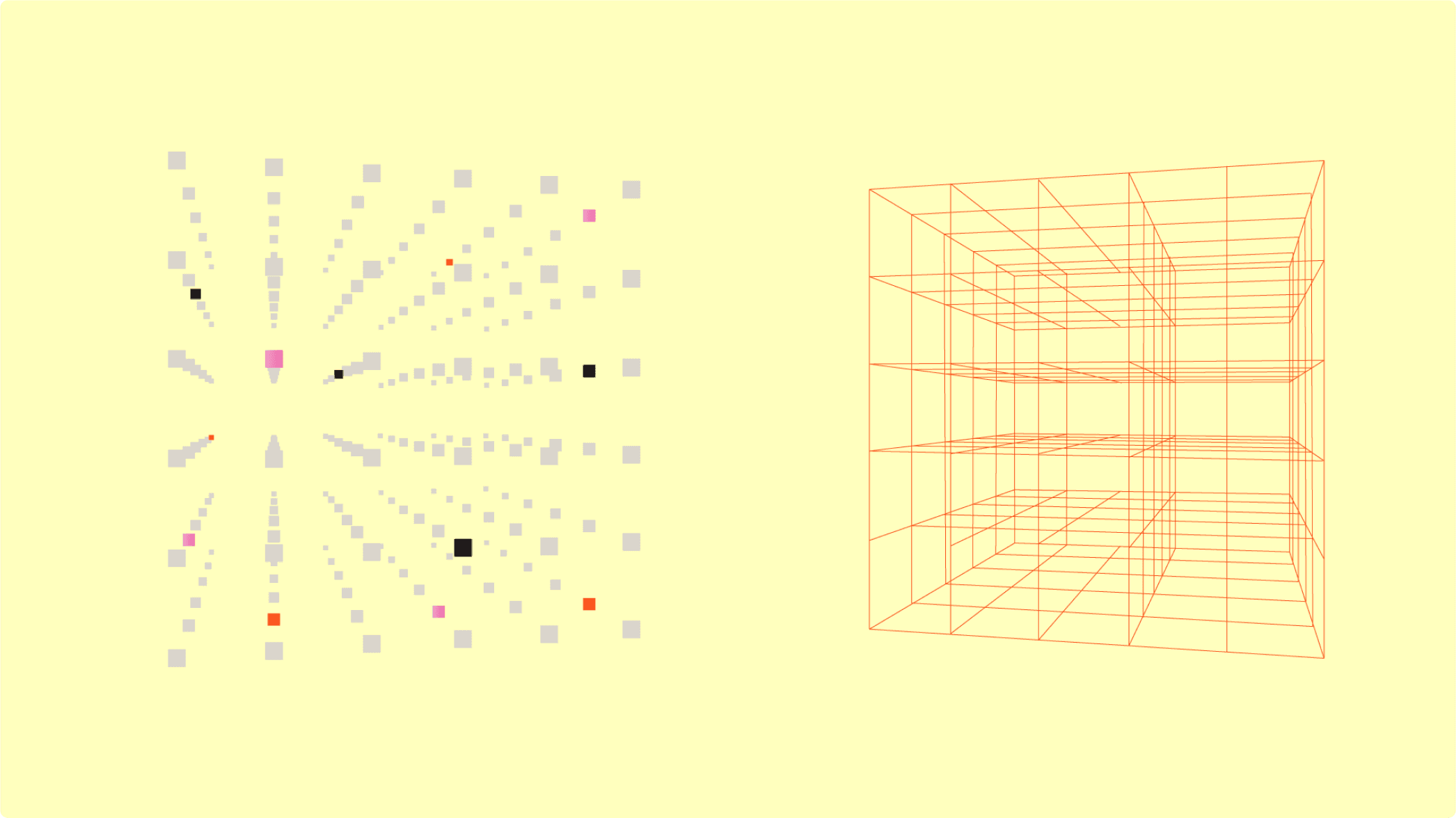

What Is the TMBR Physical Platform?

At its core, the Physical Platform is a system of mass timber objects that can be standardized and prefabricated. These objects include everything from basic structural elements to ready-to-install assemblies. The Physical Platform breaks the building process into three main categories:

TMBR Components

TMBR Assemblies

TMBR Chassis

Modular Scalability for Workforce and Disaster Relief Housing

By delivering prefabricated, modular components that require less skilled labor on-site, TMBR is uniquely positioned to meet the demands of workforce and disaster relief housing. Our scalable approach ensures communities can receive safe, efficient housing solutions when they need them most.

For more on TMBR’s modular solutions, see TMBR Typology Kits: Frame-First Solutions for Rapid Construction.

TMBR Rails: Connecting Digital and Physical Workflows

TMBR Rails serve as the digital backbone that integrates data and workflows across design, manufacturing, and assembly. By connecting all stakeholders in real-time, Rails ensure that every phase of the project is optimized for efficiency and scalability.

Mitigating Risks with Dynamic Modeling

With its ability to track progress and model dependencies, TMBR’s Rails identify potential risks—like the impact of delayed components—before they occur. This proactive approach minimizes disruptions and keeps projects on track.

For an introduction to how Rails enable seamless collaboration, explore Beginner’s Guide to TMBR Rails: The Digital Backbone of Construction Innovation

Example Workflow: From Design to Assembly

For a detailed example of how this process unfolds, explore TMBR Typology Kits: Frame-First Solutions for Rapid Construction.

Conclusion

TMBR is revolutionizing mass timber construction by bridging the gap between digital workflows and physical realities. With tools like Rails and the Physical Platform, TMBR simplifies complex processes, reduces reliance on skilled labor, and enables modular scalability for projects of all sizes.

By integrating AI-driven predictive analytics, TMBR enhances efficiency and minimizes risk across the entire project lifecycle. Whether you’re addressing workforce housing needs or delivering sustainable commercial developments, TMBR’s solutions ensure projects are smarter, faster, and more reliable.

To explore how TMBR is driving innovation in sustainable construction, check out Sustainability Meets Scalability: Why Mass Timber is the Future.